Bamboo Investment Profile

Bamboo is the fastest growing wood resource on earth and it is a viable substitute for timber and tropical hardwoods. There is a great industrial demand for it and interest in bamboo production is increasing throughout Asia, Africa, and America.

The global demand for bamboo is however already growing faster than supply can allow. The need for man-made bamboo plantations opens great possibilities for business in the agriculture and forestry sectors.

Over 1200 different species grow worldwide. Various species can reach heights of 30 m and more. About 18 million ha of bamboo are distributed in world forest ecosystems, in Asia, Africa, and America.

Unlike most timber, bamboo is a self-regenerating natural resource; new shoots that appear annually ensure future raw material after mature culms are harvested.

Bamboo provides considerable environmental benefits. In many countries, it is used for ecological purposes such as soil stabilization and erosion prevention on hill slopes and verges. It is a very important forestry plant which is harvested from existing natural forests, plantations, and mixed agroforestry systems. Bamboo silviculture is an option for conserving and protecting tropical forests while creating enduring supplies for the wood and cellulose industries.

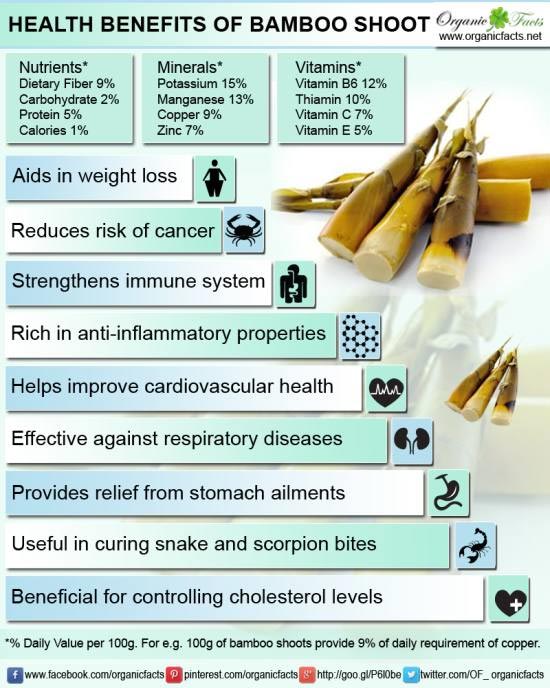

Bamboo is a multipurpose plant with a myriad of applications ranging from construction materials, furniture, fences, handicrafts, pulp and paper, edible shoots, and animal fodder. In developing countries, it is a basic raw material with numerous traditional uses. It is highly suitable for handicrafts; it can be woven into numerous products including mats, baskets, trays, hats, lampshades, caps, lanterns, etc. Many bamboo products are functional while others serve decorative purposes.

Own Your Own Bamboo Plantation

Plantations International is specialized in providing professional services for the development of bamboo investment plantations Worldwide. We offer a wide range of services to corporate or private investors, NGO’s, and forestry departments, ranging from full bamboo plantation management, technical assistance, supplying high quality planting materials, property scouting, and assistance in crop sales.

We currently manage bamboo investment plantations for timber, high fashion bamboo textiles, automotive parts, biomass, biochar, flooring, bicycles, food, furniture, garden design and modern housing and partner with experts internationally and locally to bring you ‘best practice’ in productive Bamboo Plantation and Management.

Our founders are strategic – with the long term in mind for a more ‘Balance Earth’. We know ‘Bamboo is the Future!’ as it is the most renewable, useful natural resource on the planet. It’s 10,000 uses can replace the dying Fossil industry and create jobs worldwide.

The Bamboo investment Management team and leaders are hand’s on. We partner with Indian Expert Dr. Barathi, USA expert Dr. John Woods, Columbian expert and famous Polo player Santiago Perdomo. We have researched the best processing practices and partners with University-lab’s and patents, Technology-machine processing, Design-Industrial Designers, in countless country’s from Asia, Africa to the America’s. We have developed strategic relationships with those in Governments, forestry, agriculture, manufacturing, shipping, services, and buyers of our plantation products Worldwide.

We are not just a Bamboo Investment Plantation partner with you. – we are creating sustainable wealth for you and our future. It’s your bamboo, your choice and we have different service packages for you. We are building the industry around you. Carbon Credits may apply.

Bamboo investment has a promising future in a world where environmental enhancement and forest protection have become priority concerns.

Bamboo is the fastest growing wood resource on earth and it is a viable substitute for timber and tropical hardwoods. There is a great industrial demand for it and interest in bamboo production is increasing throughout Asia, Africa, and America.

The global demand for bamboo is however already growing faster than supply can allow. The need for man-made bamboo plantations opens great possibilities for business in the agriculture and forestry sectors.

From time immemorial bamboo has proven to be a reliable material with numerous practical applications. In the 21st century it will be an increasingly valuable commodity that will be cultivated and industrially processed. We can therefore expect to find more bamboo products on the market and more bamboo materials and furniture in our homes.

Rapid Growth and High Yield

Depending on the species, bamboo plantations can remain productive for more than 50 years. Harvesting in new bamboo plantations usually begins after 5 to 7 years.

Selective harvesting can be accomplished on large plantations with specialty designed equipment or on smaller plantations with low cost equipment; a machete or hacksaw is usually all that is needed. Harvesting systems range from manually harvesting 3-year-old culms to semi-mechanical harvesting methods on small plantations.

The Bamboo Market

The market for bamboo investment is enormous and it is rapidly growing. The spread of environmental awareness coupled with stricter regulations governing the exploitation of timber resources underlie the development of the bamboo market. Bamboo is demanded more than ever before because it is at once a good timber substitute and a rainforest saver. Europe and USA import vast quantities of bamboo products from Asia, including items such as toothpicks, sate sticks, brooms, poles for viniculture and arboriculture, small bamboo sticks for the production of Azalea, Begonia and tomatoes. Products with greater added value such as bamboo parquet, bamboo laminated lumber, paper, textiles, finely crafted furniture, handicraft items and other construction industry products have gradually made their entrance in international retail markets. In the food industry, young bamboo shoots constitute a multimillion-dollar business. Bamboo shoots are produced for export in China, Thailand, China, and Taiwan. They are sold fresh and tinned, sometimes in combination with sauces or spicy foods.

Resource Development

The development of bamboo industries requires adequate and regular supplies of raw material. Sustainable bamboo management is needed to guarantee the resources for future production. So far, the main source of raw material for industrial applications are natural bamboo forests that are, in most cases, not managed at all. Natural forests normally yield between 2 to 6 tons of heterogeneous bamboo per hectare, which is only about 20% of the yield of a well-managed bamboo plantation.

Mixed natural forests with bamboo are however not easy to manage. Whilst the management of bamboo resources can be achieved by means of selective harvesting, in practice this requires more time and effort than clear felling. Management undoubtedly implies extra costs. But the cost factor is very relative considering that excessive pressure on bamboo forests is having detrimental effects which range from forest degradation to material shortages for some industries.

Due to a lack of bamboo forest management, countries like India and Bangladesh needs to plant millions of hectares to cover industrial demand, mainly by the pulp and paper industry. The main reason for this is the indiscriminate felling of bamboo which is unaccompanied by appropriate and necessary reforestation. China is experiencing a similar problem due to the over-exploitation of its bamboo resources. Some factories of bamboo products in various parts of Asia have shut down due to inadequate supplies of the basic raw materials in the proximity of the production area.

The solution to the problem lies in setting up efficiently managed bamboo plantations. A great advantage of bamboo is that it can grow in a wide variety of climates and soils, both in lowland and highland areas. Setting up new plantations is therefore feasible in many areas.

In a bamboo plantation, biomass can be sustained to maintain a green environment while maximizing the yield of raw material per hectare. A bamboo plantation of 1000 hectares can provide about 30,000 tons of wood resources, and thus renders unnecessary the cutting of over 50 thousand hardwood trees per year. This means an increase in total output and greater cost efficiency while enhancing the environment.

The Business of Growing Bamboo Investments

The cost of setting up a new plantation undoubtedly depends on inputs such as labor, land preparation, fertilizer, irrigation, and plants. Costs are therefore similar to those incurred in timber forestation projects. The big difference is that the payback period of a bamboo plantation is much shorter than that of a timber forest. Investments can be fully recovered within 10 years. The reason for this is that profits are generated faster with bamboo than with wood. A bamboo plantation becomes profitable after five years. In addition, for the same initial investment, profits can be made over a longer period of time.

One only needs to consider that mature bamboo clumps can be annually harvested. Moreover, bamboo only needs to be planted once and it can be selectively harvested for over 50 years. With timber, replanting usually has to be done after every rotation. Some fast growing trees like eucalypts can be harvested 3 to 5 times in a period of 15 to 20 years. Their fast growth usually has a heavy toll on the environment since they have a high water uptake. Bamboo on the other hand uses ground water very efficiently. So not only is bamboo more economical that eucalypts and trees, it is also more ecological.

Another very important point is that the high biomass production of bamboo makes it extremely efficient as a source of pulp. Up to seven times more pulp can be produced per hectare of bamboo compared to softwoods. This means that a significantly higher turnover can be made from bamboo than from even the fastest growing softwoods.

The overall yield and profitability of bamboo plantations can be increased by means of intercropping with timber (e.g., teak). Intercropping with other fast growing cash crops (e.g., corn, maize, tea, etc.) can also be interesting, especially as an incentive for plantation caretakers.

This makes bamboo an interesting crop for rural people as well as industrialists with large estates. A small plantation of one hectare can provide work and income for a whole family. Medium sized plantations of several hundred hectares could provide sufficient bamboo for local cottage industries and furniture makers. Larger plantations of several thousand hectares can indefinitely supply high quality raw material to a pulp mill or plywood factory. In general, bamboo provides a good investment opportunity for anyone with an interest in the agricultural and forestry sectors. So long as there is a demand for wood, bamboo farming will prove to be a lucrative business.

SETTING UP A BAMBOO NURSERY

Establishing a bamboo nursery is a practical solution for maintaining a regular supply of planting material for plantations and forestry projects. A bamboo nursery does not require high investments. Basic equipment for manual operations can be used. Several factors should be considered in selecting a site for a bamboo propagation nursery.

Location and Accessibility

If possible, the nursery should be located near a highway or public road to facilitate operations, communication and transport. Ideally, the nursery site should be as close as possible to plantation areas. This will involve less transport time and costs in delivering plants to the field. Plants will undergo less stress during transport the quicker they can be delivered to the field.

Water Supply

The nursery should be located in an area where there is an abundant and permanent supply of water. If the supply of water during the dry seasons is inadequate, a storage tank should be constructed. The amount of water needed depends upon the nursery size, watering frequency, rainfall and climatic conditions, the species to be raised, the quantity of propagation materials, and the method of watering to be employed.

Soil and Topography

Local topography is a crucial factor and ideally, the site should slope gently to about 5° so that rainwater can run off without causing erosion. In general, hilltops and valley bottoms are unsuitable; locations on middle to lower slopes are preferable. The nursery production requires well-drained and fertile soil with a medium to light texture.

Sun and Shade

Plants in a nursery need a good balance of sunlight and shade. Sites that are heavily shaded throughout the day should be avoided. Partial shading is desirable in the very dry areas to prevent excessive day temperature. Arid areas with desiccating conditions are not suitable for a bamboo nursery.

NURSERY SIZE AND LAYOUT

The size of the nursery depends on its intended production capacity and on the size and age of plants to be grown. A nursery dedicated to the production of young liners or seedlings which are to be delivered to other nurseries will require less space than a nursery which grows and stocks older and larger plants.

On average, the amount of time bamboo seedlings has to remain in the nursery ranges from 8 to 12 months. In general, at least 5000 m² should be allotted for every 10,000 seedlings or young plants that will be raised annually. If seedlings will be grown at the nursery until they are 2 years old, then the area needed for production should be doubled. Adequate space is needed to maintain a stock of growing plants. A crowded nursery will only result in the production of poor stock quality.

The shape or layout of the nursery should be approximately square to minimize the length of the perimeter. This will not only reduce the cost of fencing the nursery, but will also enable faster movement of workers from one point of the nursery to another. The area needed for paths, roads, irrigation, ditches, and buildings should also be taken into consideration, and represents additional space requirements to the entire nursery unit. Having more land than initially required provides an allowance for future expansion of the nursery production area.

PREPARATION OF THE OPEN NURSERY FIELD

Clearing and leveling of the land is the first step. The open field should be at a gentle slope of about 5° to ensure water run-off. The ground must be flat to prevent the water from accumulating in puddles. This is imperative because the bamboo plants will be cultivated in polybag tubes, which must never be submerged in water. The drainage system must be well planned. Gutters and trenches should be dug out to prevent water from flooding the container field.

As mentioned, using ground cover cloth is a proven way of reducing the risk of grasses and weeds from infesting the open field production area. The synthetic woven fabric is made of tough UV stabilized polypropylene yarns and is designed to inhibit weed growth and improve the appearance of the nursery. It blocks sunlight and thereby prevents weeds from infesting the potted plants while allowing water and nutrients to freely pass through the soil. The use of ground cover fabric eliminates the need of applying large quantities of herbicides to the soil prior to bringing in the potted plants. While weed control through the application of herbicides implies a lower initial cost, it however involves work and maintenance all year long. The use of a ground cover cloth involves a moderate investment, but weed control will be more effective and requires less maintenance and labor. This option should therefore be considered depending on the purpose of the nursery and production scale that is forecasted.

Clumping Vs. Running Bamboos

There are two main types of bamboo, Noninvasive clumping bamboos (sympodial or pachymorph) have short roots and form discrete clumps. There are also a few species of clumpers which have slightly longer roots (6-18″), and we refer to these as open clumpers. Running bamboos (monopodial or leptomorph) are the ones that spread through the growth of long, horizontal roots, called rhizomes. With a little knowledge and proper materials, running bamboos and open clumpers can be effectively contained.

Clumping bamboos have a very short root structure, are genetically incapable of expanding more than few inches a year, and will generally form discrete circular clumps. The clumps slowly enlarge as new culms emerge every year, but may ultimately need to expand to anywhere from a 3 to 10 ft. diameter (or more, especially for taller types) in order to reach their mature height, depending on species. The dense root system can exert strong pressure on structures in contact with it, and thus clumpers should be planted at some distance from fences, sidewalks, retaining walls, etc. Clumpers make excellent specimen plants and will also form very dense screens, but more slowly than runners. Except for the Fargesias, clumpers tend to be less cold-hardy than runners.

Running bamboos spread variously, sending out underground runners (rhizomes) which sometimes range far from the parent plant. Runners fill in the spaces between plantings faster, making them ideal for fast screens, hedges, and the popular open grove look. Bamboo runners may be easily contained, since the rhizomes grow sideways at a depth of only about 2-18 inches. Most are also very cold-hardy.

Bamboo Plantation Climate Requirements

Optimal climate conditions to grow bamboo together with soil properties will determine to a large extent whether the development of a commercial bamboo plantation will be successful or not. 7 climatic variables must be studied and researched before establishing a commercial bamboo farm in a given location. They are; average annual temperature, altitude, annual average rainfall (precipitation), latitude, average hours of sunlight per year, relative humidity, and average wind speed.

1. Temperature

Bamboo shows great adaptability in terms of temperatures, it can be found in warm and more temperate climates and can adapt to various environmental conditions. The lower limit of adaptability for clumping bamboo corresponds to a minimum average temperature of 16°C, and the maximum average temperature is 36°C. The optimal temperature ranges to grow clumping bamboo lays between an average temperature of 20°C and 26°C.

2. Altitude

Under optimal condition bamboo grows best at altitudes between 200 m and 1600 m above sea level, although it can been found from 0 m (sea level) up to 2400 m above sea level. The, height above sea level is directly related to temperature. It is the average temperature that plays the decisive role in the development of bamboo, and not, while being important, the height above sea level.

3. Precipitation

From all the climate factors, precipitation or rainfall is the most important variable. If all other conditions are optimal but precipitation is lacking, the development of the bamboo farm will be affected remarkably. Bamboo can be developed in areas where annual rainfall ranges between 1270 mm and 5000 mm, but the optimal development of bamboo clumps occur when average annual precipitation ranges between 2000 mm and 2500 mm.

Moreover, it is not so much the total amount of rainfall per year but the even distribution of those rains throughout the year that highly favor the growth of bamboo plantations. Soils with high water tables foster the development of the species because they can uptake water from the soil during dry periods as well.

4. Latitude

Growing bamboo at 1200 m in Thailand is not the same as planting at the same altitude in Australia or other countries, because the latitude in other countries alters the optimal variables of altitude and temperature. Different latitude under the same altitude, will result in different average temperatures. To establish bamboo under different latitudes, you should consider that for every 4 degrees of latitude you move to the north or south of the equator line of cultivation, the site will lose 1°C in temperature. Also for every 160 m that you change in altitude (upwards or downwards) you will win or lose 1°C in temperature.

5. Sunshine

In this regard it is preferable to look for areas with more light than those who remain continuously cloudy. The optimal solar conditions for the development of bamboo should be between 1800 and 2200 hours / light / year. Studies have shown that more sunshine improves the vegetation development of a bamboo plantation.

6. Relative Humidity

The optimal relative humidity range most favorable for bamboo farms is between 75% and 85%. For commercial plantations the relative humidity is best in tropical areas, with the presence of rivers or lakes. When the plantation is 2 years old, bamboo will start creating its own optimal relative humidity for their best development.

7. Wind

It is essential to find information on the wind speed in the area where they want to establish a plantation. Wind speeds over 80 km per hour can cause development problems to bamboo plantations.Optimal wind speeds are usually up to 15 km / hour and are called a breeze. When winds speeds reach over 80 Km / hr they can produce mechanical damage in bamboo. These velocities of wind present breakage (with very young stems) and mature stems might fall over. Highly exploited bamboo plantations are prone to stems falling over because there is no support between them.

Bamboo Soil Requirements

Most bamboos grow best in deep, well-drained, fertile soils, and they generally prefer neutral to slightly acid soils. If your soil is deficient, the extra time and expense of improving it is usually well worth the effort. Sandy soils and alkaline soils may be improved with the addition of organic materials such as compost, peat, manures, nitrolized sawdust, or bark chips. These materials help retain moisture, acidify the soil, and also provide nutrition to the plants. Acid fertilizers can also be added to compensate for extremely alkaline soils. For overly acidic soils with pH of 5.5 or lower, add lime to reduce acidity to a pH of 6.0 – 7.0. Clay soils may be improved to provide better drainage with the addition of sand and organic materials. Most bamboos suffer root damage if submerged in water for several weeks. Drainage may also be improved by mounding the soil or ditching around the planting. Bamboos can be grown well in very shallow soils if adequate fertility and moisture are maintained

Growing Bamboo from Cuttings

Growing bamboo cuttings is a very popular bamboo propagation method because it’s fast, simple, economical, and it doesn’t require a lot of space. Thick-walled bamboo species have prominent primary branches. These branches can be extracted without damaging the mother clump and are often (depending on the bamboo species) an excellent planting material.

Select a culm and trim the primary branches. Branches should preferably be cut at a young to intermediate maturity (1-2 years) to guarantee a high survival rate. Discard the top portion leaving 2-3 nodes and the basal swell. These bamboo cuttings are usually around 30cm long.

Alternatively, (to give faster results) dip the bamboo cuttings in a growth regulator mixture or rooting hormone for 24 hours, and seal the top cut end with wax to prevent desiccation. Plant the bamboo cuttings vertically (preferably in a slight angle), either in poly bags or raised beds in such a way that the rhizomatous swelling and one node remain below the soil surface and at least one or two nodes above the surface.

PLANTING PROCEDURE FOR NURSERY PLANTS

The following guidelines are suggested to aid the establishment of a productive plantation.

- When selecting the plantation site, check the quality of the soil. Bamboo can grow well on most soil, but deep porous fertile soil with high moisture content and a pH of 5.5 is preferable.

- Good soil drainage is very important. Verify that the land is not prone to flooding. Bamboo does not perform well on waterlogged soils. It is therefore preferable for the plantation to be situated on moderate slopes.

- Clear the land of all weeds and unwanted vegetation. Burning may be necessary during the dry season.

- Carefully plan the layout of plantation so that the planting holes are placed at the specified distances and intervals.

- Plan the activities so that the plantation layout is completed at least 2 weeks before planting.

- The planting holes should be positioned in a north-south orientation. This will provide an optimal distribution of sunlight to all the plants.

- Planting should coincide with the start of the rainy season. If available, organic fertilizer or manure should be placed into each hole and mixed with the topsoil. The plants should be planted vertically in an erect position and the hole should be properly covered and mulched.

Bamboo Plantation Weed Control

The growth of bamboo plants can be hampered by weeds and competing vegetation. It is very important to control and arrest the growth of weeds around each bamboo clump. Failure to do so will invariably result in poor root and stem development in the young bamboos. An area within a radius of 60 cm around each plant should be cleared of all weeds and vegetation.

Weeds compete with bamboo plants by absorbing nutrients, water, and sunlight. Weeds have rhizomes which sprout again if not removed. Measures to control weeds include a thorough preparation of the soil before sowing and the use of sowing media and manure which are free of weed seeds. The removal of weeds growing within the vicinity is also strongly advised in order to lower the occurrence of seed dispersal by wind or water. The following are recommended practices in weeding:

- Weeding should be done thoroughly, systematically and regularly.

- When removing weeds from soil, no portion of the root system should be left behind.

- Weeding should be done only when the soil is moist.

- Weeds that have been removed should be properly disposed of in a rubbish heap.

- Wherever practical and convenient, mechanical weeding tools may be used.

Pest and Diseases

Bamboo Plant Diseases A healthy stand of bamboo is surprisingly resistant to pests and diseases. Even so, you may occasionally notice spots and discolorations that indicate problems. Preventing Bamboo Diseases, It’s easier to prevent bamboo plant diseases than to cure them once they take hold. Good growing conditions promote healthy plants that resist diseases.

Fungal Spots

Fungal spots, like rust, sometimes appear on older plants. The spots are round and mostly cosmetic. They appear most often in humid climates. You can treat the disease with a copper-based fungicide, but since the plants that have spots are old, consider culling them to make room for younger, more vigorous plants.

Bamboo Mosaic Virus

This virus is usually acquired in a nursery setting where it is transmitted on the blades of pruning tools. The first symptom is a mosaic discoloration pattern on the leaves. You will eventually see dieback beginning at the top of the plant. There is no cure for the disease, but you may be able to keep the plants alive for a while with aggressive pruning. Remember to sterilize pruners between cuts.

Sooty Mold

Sooty mold is caused by small, sucking insects such as mealybugs, aphids and scale insects. As these insects feed, they excrete a sticky substance called honeydew. The honeydew quickly becomes infested with the sooty mold fungus, causing unsightly black spots. You can wash it off the plant, but as long as you have an insect infestation, it returns repeatedly. Get rid of the insects with frequent applications of insecticidal soaps or oils. Follow the label instructions, and apply as often as the instructions allow until the insects are gone. With oils, it is important to follow the timing guidelines on the label.

Rot Issues

Root rots and heart rots also affect bamboo. Heart rot is a fungus living inside the stems and can occur in any part of the stem. Root rot affects the roots and lower part of the stem. Either type of rot may be accompanied by mushrooms growing on the bamboo or on the soil at the base of the plant. These diseases can’t be cured and will eventually kill the plant. Remove the plants, taking care to remove all of the roots to prevent the spread of the disease to other plants.

Water, Manures and Fertilizers

Maintaining bamboo is not especially difficult, for the first two years, make sure that your plant is well watered. This is essential. Bamboos can be greedy feeders, but they can also thrive quite happily with one decent feed in spring with an all-purpose organic fertiliser. In essence, the more you feed a bamboo plant, the more it will grow. This is why you can limit its growth by limiting its nutrient intake. Be aware that bamboos are intolerant of salt and therefore may react badly to seaweed based fertilisers. Make sure that the area around your plant is always well mulched. This helps retain moisture and maintains an even temperature around the roots of the plant. You’ll notice that the plant builds up its own mulch of leaf litter and shed culm sheaths in time. But you will do nothing but good to the plant if you add to this with organic mulches, like bark, wood chips and leaf mold.

PLANTATION MAINTENANCE

Maintenance activities during the first 2 years after planting must focus on protecting the young plants from competing vegetation and pests. After the second year, maintenance activities are concentrated on clump management.

SOIL MAINTENANCE

During the first year, it is advisable to loosen the soil around the plant to improve soil aeration. Doing this about twice a year for each plant will enhance growth. Care should however be taken not to disturb the rhizome system of the plant.

MULCHING

Mulching is a proven way of improving the growth of bamboo. In drier areas, with rainfall less than 1000 mm, mulching around plants greatly encourages growth through reduced evaporation of soil water. Mulching is achieved by uniformly spreading a layer of leaf litter or other organic material on the surface of the soil around the bamboo clump. Mulching is an effective way of preventing weed growth. It helps conserve soil moisture and contributes organic nutrients to the plant.

Mulching is absolutely necessary for the production of good quality bamboo shoots. The mulch protects young shoots from direct sunlight and keeps them moist, thus allowing them to grow to an optimal size without hardening and losing their edible quality.

CLUMP MANAGEMENT

The proper maintenance of the clump not only improves productivity but also eases the job of the plantation worker. Clump management is partly a maintenance task and partly a result of harvesting. As a maintenance activity, it involves removing unwanted culms to prevent clump congestion. This is particularly necessary with densely tufted species. About 90% of new culms emerge in the outer borders of the clump. New shoots and culms cause the clump to widen in diameter. Culms at the periphery of the clump are generally new or young, while older culms stand towards the interior of the clump. Understanding this is important for maintaining a bamboo clump such that its productivity and vigor is maximized.

In maintaining a bamboo clump, it is necessary to extract the oldest culms in the interior of the clump. This is facilitated by creating an opening in the clump, and shaping the clump in the form of a horseshoe or “C shape”. Unless properly managed, clumping bamboos tend to get congested resulting in deterioration both in quality and quantity. It is difficult to extract culms from congested clumps. Preventing clump congestion is important so that harvesting can be done with greater ease. Thinning the clump is essential to provide space for the emergence of new shoots. It is sometimes necessary to sacrifice a few young culms in order to allow for better shoot production in the clump.

Removal of old and rotting culms is also necessary to promote the healthy growth of shoots and new culms. Special attention should be placed on rotting in the stubs of culms that have been harvested. If rotting becomes apparent, it is advisable to dig around the stub and completely remove it. Likewise, rotting culms should be extracted.

HARVESTING AND HANDLING

Harvesting should be done selectively according to the age and maturity of the culms. Systematic and selective cutting of mature culms assures the continuous production of young shoots, which is an index of annual yield or increment. The implementation of plantation management strategies can help sustain the regenerative characteristics of bamboo and thereby provide an enduring supply of raw material for industries.

The bamboo plantation will be managed effectively if the exploitation is regulated on a sustainable yield basis. In other words, the clump should never be over harvested or clear cut. New culms as well as 1 to 2-year-old culms should not be harvested. A few 3-year-old culms should also be left standing so that the clump remains robust and so that harvesting can be performed annually. Following this method, culms are left standing on the clump until they mature, after which, they may be harvested. A newly established plantation of clumping bamboo should normally be ready for first harvesting after 5 to 6 years from the time of planting. Thereafter, cutting of mature culms can be done annually or at predetermined intervals of years, according to the management plan and the end use of culms. The cutting cycles and methods of extraction of culms from a clump should be implemented as an integral part of the management system of bamboo plantations and natural bamboo stands. Achieving sustainability in terms of culm production will therefore depend on how effectively culms are selected for harvesting, and on how the extraction from the clump is carried out.

POST-HARVEST TREATMENT

Bamboo culms are vulnerable to decay and attack by fungi or insects, especially powder post beetles. Such attacks reduce the natural durability of bamboo and diminish their value and utility. Post-harvest treatments can help to reduce the risk of decay and attack by pests and thereby increase the useful life and value of bamboo culms. Depending on the end use of the culm, several methods of preservation may be applied to culms prior to their sale or industrial utilization.

DRYING AND SEASONING

Drying culms is common in the processing of bamboo culm for most uses. Culms are also subjected to seasoning prior to machining, processing, and finishing products that are durable, stable and of a high quality. Bamboo culms can be air-dried with or without sunlight or they may be kiln-dried. Air-drying is more common that kiln drying since it is more economical. Bamboo culms may be split into halves to speed up drying operations.

Bamboo culms may be thoroughly air-dried in well-ventilated shade for several weeks. Drying requires horizontal stacking of culms on racks. In drying large quantities, the butts and tops of the culms are placed alternately then tied in bundles to prevent bending. Straightening green culms without application of heat requires several weeks. This is done under the shade, either by suspending the freshly cut curved culm by the tip and attaching a weight at the other end, or by laying the green culm on a flat surface and applying sufficient pressure over the culm during the period of drying and setting.

To find out more about how Plantations International can assist you with the development and management of your own bamboo plantation on your land and to receive a free initial consultation, please call us today on +852 5808 3775 or Click Here to contact your nearest Plantations International representative.

.